This ‘Elektron-V’ system could produce up to 1900

liters per day, with an average power load of 860 watts. Its mass was 150

kg. The design lifetime was 3 years and the First unit operated for three

and a half years.

WHERE THE ‘ELEKTRON’ IS BUILT

The system was developed and fabricated by a corporation called

Niichimmash, also transliterated NIIKHIMMASH. In English, this means

“Scientific-Experimental Institute of ChemicalMachine-Building,”

in Sergiyev Posad (Zagorsk), near Moscow. It also builds chemical

rocket engines and other chemistry-related products, including for

the Russian military.

In 1992, visiting NASA engineers were shown an Elektron

unit that weighed 110 kg and expended 3385 watt-hours per lb of

oxygen (a comparable US unit made by Hamilton Standard, the

‘SPE’, uses 2400 watt-hours per lb of O2). The unit

used a circulating KOH electrolyte, and the hydrogen and oxygen

product gases are separated from the water using ‘static separators’.

|

|

The unit was in a titanium housing with a nitrogen blanket. The oxygen

is not stored but is discharged directly into the cabin at 45 psi. Hydrogen

is vented overboard although there was hardware to divert it to a planned

Sabatier Reactor for CO2 reduction (never installed).

Niichimmash had one Elektron unit without pressure shell, for classroom

training, and two flight units, one that had been operating since 1985

to “lead” the Mir flight unit, and the other available for

mission support and off-nominal tests. Another flight unit was at Star

City for cosmonaut training.

TECHNICAL SPECIFICATIONS

In the September 1993 3rd Edition of “Soviet Space Stations As Analogs”,

B.J. Bluth and Dennis Fielder, produced by Grumman Aerospace in Reston,

Va., section 1.4.7.3.4 (p. I-238) contains technical data on the

electrolysis reaction. Electrolysis of pure water at normal temperatures

is enhanced by the presence of an alkali to support ionization and increase

conductivity:

KOH = K+ + OH-

Maximum electrolyte conductivity can be achieved with its concentration

at about 30% KOH. At the anode, negative ions of the hydroxyl group OH-

migrate towards the positive anode and discharge, releasing electrons

4 OH- - 4e = 2H2O + O2 , releasing oxygen and forming water, while water

molecules combine with the hydroxyl molecules, migrate to the cathode,

oxidize, and release hydrogen thusly:

2H2O + 2e = 2 OH- + H2

According to this document, the Mir electrolysis system had a mass of

140 kg, had twelve cells each with a cell voltage of 2v and a size of

0.8m x 0.13m, used 800 w with max current at 2V of 400 amp.

NASA TRAINING MANUAL ON ‘ELEKTRON’

From the “NASA Familiarization Manual on Russian Segment Crew Systems”,

Published in 1997.

3.1. Oxygen Supply System

The oxygen supply system of the Russian segment consists of the Elektron

unit, two solid fuel oxygen generators (TGK), and deliverable oxygen from

the Progress cargo spacecraft.

The Elektron unit is the prime source of oxygen and operates on the principle

of the electrochemical decomposition of water. The TGK and the Progress

deliverable oxygen are auxiliary sources of oxygen.

The Electron consist of a liquid loop with 30-percent potassium hydroxide

(KOH) in solution, gas lines with a pressure regulator, and electromagnetic

valves (KEh). The liquid loop is placed into a pressure-tight hull pressurized

with nitrogen for safety reasons. External to the pressure-tight hull,

the liquid loop is connected to a water tank (YeDV), which is replaced

periodically.

The Elektron unit is installed behind

panels 429 and 430 in the SM.

The liquid loop includes an electrolysis unit, two heat exchangers, a

pump, and an internal water storage tank. The pump provides the circulation

of the electrolyte through the electrolysis unit. The internal water storage

tank acts as a membrane pump to replenish the amount of water decomposed

into oxygen and hydrogen.

The pressure regulator maintains a preset pressure differential in the

oxygen and hydrogen lines.

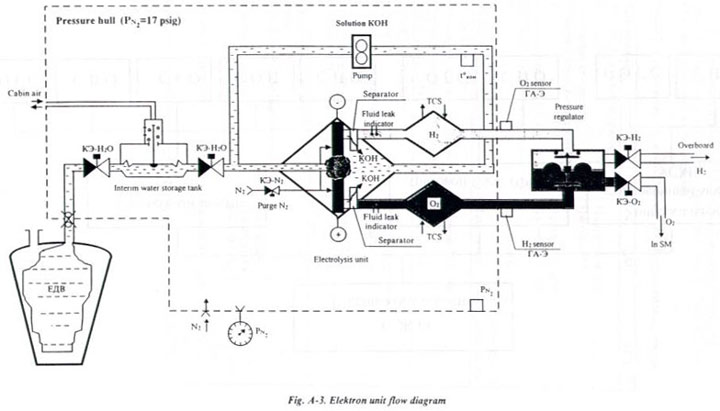

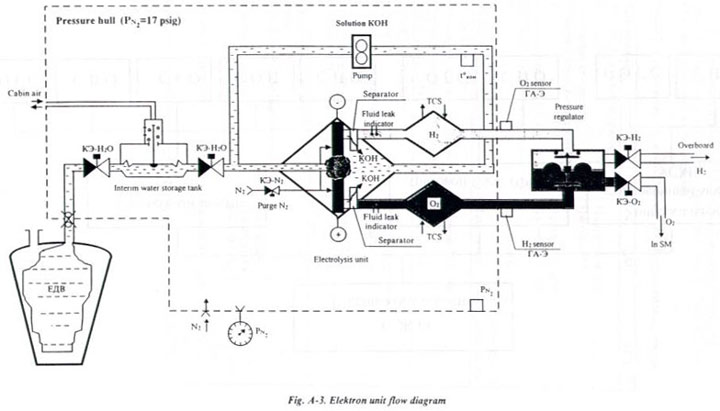

Fig. A-3 shows a diagram

of the electrolysis process. Oxygen is generated in the system by

the electrolysis of the water content in potassium hydroxide solution.

Water is made up of 89% oxygen by weight. The reaction breaks down water

into its constituents of oxygen and hydrogen. The oxygen is released directly

into the atmosphere of the SM and the hydrogen is vented to vacuum. The

electrolysis unit is made up of 12 electrolysis cells which are enclosed

in a blastproof housing. The cells are cooled by the thermal control system

(STR). The decomposition of 1 kg (2.2 lbs) of water yields 25 L (0.88

ft3) of oxygen per hour at a pressure of 760 mmHg, which is enough to

support one crew member for one day. To provide the daily amount of oxygen

for 3 - 4 crew members, 3 - 4 kg (6.6 - 8.8 lbs) of water must be decomposed.

Power consumption of the process is ~ 1 kW.

The Elektron unit is controlled by the on-board computer system. The

following parameters are monitored in the process of operation: valve status,

oxygen and hydrogen pressure internal to pressure hull of the Elektron,

hydrogen concentration in the oxygen line, and oxygen concentration

in the hydrogen line.

If the hydrogen pressure in the oxygen line reaches 2% of the total line

pressure, the signal “GA-Eh srabotal” (GA-Eh response to maximum

value) is transmitted to the Integrated Control Panel (InPU) (Fig. B-I).

A similar signal is generated if the oxygen pressure in the hydrogen

line reaches 2% of the total line pressure.

Another signal “Prover elektron” (Test Elektron) is transmitted

to the Integrated Control Panel (InPU) if any of the following conditions

occur:

• temperature of the electrolyte reaches 65ºC

(150ºF)

• oxygen pressure in line exceeds 0.65 kg/cm2

(9.5 psig)

• pressure of the interim water storage tank drops

below 900 mm H20

• nitrogen pressure in the pressurized hull

drops to 0.9 kg/cm2 (13.3 psig)

• differential pressure between

oxygen and hydrogen lines exceeds 500 mmH2O

• electrolyte

is detected in the hydrogen or oxygen lines.

For either of the signals described above, the Elektron will perform an

automatic shutdown

|